近日,《中国冷冻调理食品行业发展现状分析与投资趋势预测报告(2022-2029年)》发布,报告显示,冷冻调理食品是冷冻食品五大类之一,是继冷冻畜产品、冷冻禽产品、冷冻水产品、冷冻果蔬产品之后,又一个冷冻食品的主要大类。冷冻调理食品是指以农产、畜禽、水产品等为主要原料,经前处理及配制加工后,采用速冻工艺,并在冻结状态下(产品中心温度在-18℃以下)贮存、运输和销售的包装食品。

1

发展现状

1、冷冻食品行业现状

速冻食品是指以米、面、杂粮等为主要原料,以肉类、蔬菜等为辅料,经加工制成各类烹制或未烹制的主食品后,立即采用速冻工艺制成并可以在冻结条件下运输储存及销售的各类主食品。

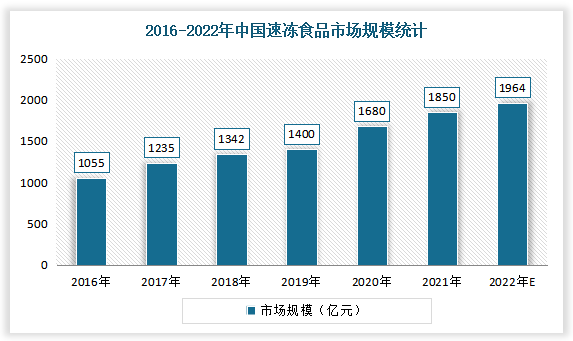

近年来随着生活节奏越来越快,而且烹饪环节多而复杂,导致年轻人下厨时间较少,意愿也不强烈。外卖虽然越来越便捷、普遍,但常被曝出各种健康、卫生问题。而速冻食品既满足了容易烹饪、食材营养的要求,又顺应了年轻人懒、宅的心理,因此逐渐受到消费者的青睐,使得行业迅速成长。 数据显示,2021年我国速冻食品的市场规模达1850亿元。预测2022年我国速冻食品的市场规模将突破1900亿元。

2、冷冻调理食品行业现状

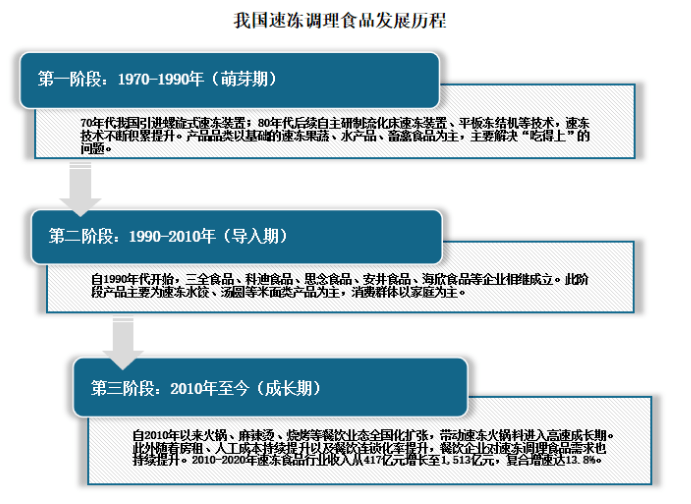

我国冷冻调理食品行业开始发展于1970年,但初期由于平板冻结机等技术问题,产品品类以基础的速冻果蔬、水产品、畜禽食品为主,主要解决“吃得上”的问题。到2010年,随着火锅、麻辣烫、烧烤等餐饮业态全国化扩张,以及房租、人工成本持续提升以及餐饮连锁化率提升,餐饮企业对速冻调理食品需求也持续提升,行业才开始快速发展。

发展到目前,我国冷冻调理食品行业主要经历了三个阶段,分别是萌芽期、导入期、成长期。现阶段我国冷冻调理食品正处于成长期,年复合增速达13.8%。预计未来10年我国速冻调理食品行业仍有望处于成长期,预计CAGR10%左右。

2

细分市场现状

速冻调理食品主要有面点类、分割肉、肉制品类、调味配菜类等种类。

1、速冻调理面点市场

速冻调理点心类食品一般用面粉、稻米、杂粮、豆类等原料制作,常为带馅点心。常见的速冻点心类主要有饺子、春卷、包子、粽子、汤圆、八宝饭、烧卖、窝窝头、馄饨、速冻花卷等。

(1)速冻饺子

速冻水饺是将包好的饺子经过速冻以达到冷藏,可以随时食用的一种食物。饺子是受中国汉族人民喜爱的传统特色食品,是每年春节必吃的年节食品。

近年来伴随着生活节奏加快,家务劳动社会化趋势将更加明显,可以发现中国外食和速冻食品的消化量也在逐年提高。速冻水饺作为中国速冻食品的较大品类,其发展已经相当成熟,“宅经济”带来的红利让各大企业利润激增。此外大品牌凭借着认可度和渠道优势,已经逐渐构筑了一定的壁垒。

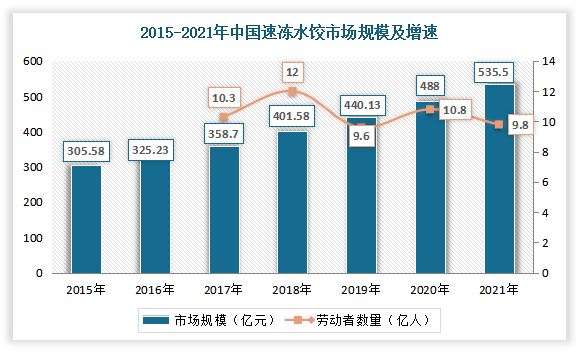

根据数据显示,2020年我国速冻水饺产量约为254.1万吨,同比增长22.8%;需求量为239.2万吨,同比增长7.8%。到2021年我国速冻水饺市场规模约为535.5亿元,同比增长9.8%。

(2)速冻春卷

春卷是我国流传已久的一种传统节日食品,在立春时节吃春卷常被视为“迎春”的一项准备。春卷,又称春饼、春盘、薄饼,或以豆沙、蔬菜制作素馅,或以肉类搭配卷心菜、粉丝、荠菜、芹菜、香干等制成荤馅,用一张春卷皮包裹住馅料后,再经炸制即可得到酥脆爽口的美味春卷。

近几年来随着春卷在海外大受欢迎,有效弥补了国内市场主要以冬春两季销售为主的现实困境,为春卷市场注入了活力。而在此背景下,速冻春卷也得到了发展机会。据了解,速冻食品生产主要是通过速冻设备在-18℃以下的环境中对食物进行急速低温冷冻,这样的方式能够更有效地锁住食物中的水分、汁液,还能遏制微生物的繁殖,食物口感、品质和保质期限都能得到提高,对于春卷而言就能更好地还原蔬菜等馅料的风味。

(3)速冻包子

包子是中华民族传统的特色美食,是一种由面和馅包起来制成的食品。包子在我国历史十分悠久,有些包子种类已全国知名,比如狗不理、叉烧包、小笼包、灌汤包、肉包子、奶皇包、豆沙包等。

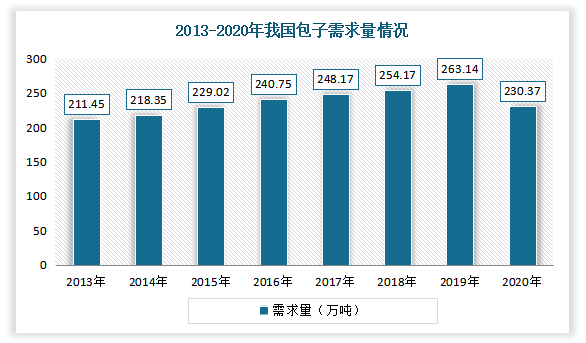

包子皮馅兼有 ,更为美味且富含营养,深受我国人民的喜欢。近年来随着居民生活方式的改变与提升,包子的需求量快速攀升。2019年我国包子需求量从2013年的211.45万吨增长至263.14万吨,2020年受疫情爆发影响,下降至230.38万吨,同比减少12.45%。

与此同时,随着我国食品制造业从传统手工生产逐步转向机械化运作,速冻包点不断发展。由于顺应了年轻人懒、宅的心理,因此速冻包点逐渐受到消费者的青睐,需求量不断增长。整体来看,2010-2020年期间,速冻包点走势与整体包子需求量走势一致,也是2013-2019年呈现不断增长态势,2020年受疫情爆发影响,下降至38.26万吨。

市场规模方面,与行业需求量走势一致。2013-2019年呈现不断增长态势,2020年受疫情爆发影响,下降至91.54亿元,同比下降7.04%。但受益于电商等渠道的影响,规模降幅低于现制类产品(同比下降11.51%)。

(4)速冻小笼包

小笼包是我国传统的米面食品之一,据说其发展历史可以追溯至北宋时期,是由灌汤包演变而来的一种面点,“一提一吸”间更是尽享其汤汁、馅料等众多风味,后来主要在江浙沪一带继续传承与发扬并延续至今,也涌现出知味观、又一村、南翔、万寿斋等众多深受人们青睐的品牌。

近年来随着便捷化的消费需求增长,以速冻米面食品、速冻火锅食材为代表的速冻食品市场迎来快速扩增期,并在10%左右的年复合增长中迈向千亿级别新台阶,据相关数据显示到2020年我国速冻食品市场规模或达到1458亿元。

而伴随着人们对食品多元化、品质化的需求不断提升,诸如速冻米面类食品中除了常见的水饺、汤圆、馒头、包子外,皮薄馅多、鲜美多汁的小笼包也成为速冻食品市场加速细分中的一大品类。

这主要得益于近年来食品生产工艺不断升级,以—40℃下的速冻工艺加工得到的生胚发面小笼包并非熟制后冷冻,能够更好地还原小笼包风味,且加热时无需解冻,较好地满足了人们对时间、品质的双重升级需求。同时,眼下市场中涌现出的各个品牌还为人们带来了鲜肉、梅干菜鲜肉、虾仁三鲜、菌菇、蟹黄等众多风味的小笼,充分满足了不同群体的多元化需求。

(5)速冻汤圆

汤圆,别称“汤团”“浮元子”,是汉族传统小吃的代表之一。同时,也是中国的传统节日所最具有特色的食物,也表达了古代人民对幸福生活的一种向往和期盼。据传,汤圆起源于宋朝。当时的明州(现浙江省宁波市)所兴起的一种新奇食品,即用黑芝麻、猪板油做馅、加入少许白糖,外面用糯米粉搓成圆形,煮熟后,吃起来香甜软糯,回味无穷。同时,汤圆象征合家团圆美满,吃汤圆也意味着在新的一年里合家幸福、团团圆圆,所以是正月十五元宵节必备美食。

汤圆在速冻食品当中仅次于火锅食品类(鱼丸等)、肉类(牛肉等)、饺子类之后,位居第四位,并且比例接近一半。这显示出,汤圆是国人非常喜爱的速冻食品之一。如果是临近元宵节等消费旺季,汤圆的市场关注度更高。

2、速冻调理肉制品类

速冻调理肉制品是指以畜禽肉为主要原料,绞制或切制后添加调味料和其它辅料,经滚揉、搅拌、调味或预加热等工艺加工而成的非即食类肉制品。

调理肉制品需在冷藏或冷冻条件下贮藏、运输及销售,食用前需经二次加工。常见的调理肉制品有骨肉相连、鸡柳、重组牛排、盐酥鸡块、奥尔良鸡翅等。由于调理肉制品预先经过处理,食用前仅需进行加热处理即可,加之种类繁多、营养美味,因此备受消费者喜爱。

3、调味配菜类:预制菜

随着近几年冷链技术快速发展,预制菜行业配送障碍逐渐消失,自2015年之后,行业进入快速发展期。2020年以来新冠疫情导致了居家消费的新趋势,由于近期疫情管控形势趋严,各地倡导就地过年,进一步刺激了预制菜市场消费。2021年我国预制菜市场规模已超3千亿元,年复合增长在20%左右。

虽然近几年我国预制菜行业发展较为快速,但目前仍处于起步阶段。预计随着社会经济的发展,我国居民收入快速提升,居民饮食消费升级,消费习惯被逐步培育,预制菜市场将得到快速发展。与此同时,当前生活节奏加快,人们对于饮食品质的要求却未降低,在消费升级潮流的推动下,消费者对于绿色、健康、美味的食品需求大幅提升。由此可见,我国预制菜市场具有广阔的市场前景。